Refurbishment: Software to Transform Your Business

Refurbishment has become an essential pillar for many businesses seeking to maximize the lifespan of their products while reducing costs and waste.

Refurbishment Revolution

The refurbishment market represents €15 billion in Europe and grows by 20% annually. Leading companies now use software solutions to maximize their efficiency.

Refurbishment has become an essential pillar for many businesses seeking to maximize the lifespan of their products while reducing costs and waste.

But how can you ensure this process is both efficient and profitable?

This is where refurbishment software comes in.

What you'll discover in this article

- How refurbishment software can transform your operations

- Concrete advantages over manual methods

- Why Refit stands out as the leading solution

- The most profitable application sectors

In this article, we'll explore how refurbishment software can not only optimize your operations but also significantly transform your business.

We'll cover the key benefits of using software, how it compares to traditional manual methods, and why choosing the Refit solution could be the best decision for your business.

What is refurbishment software?

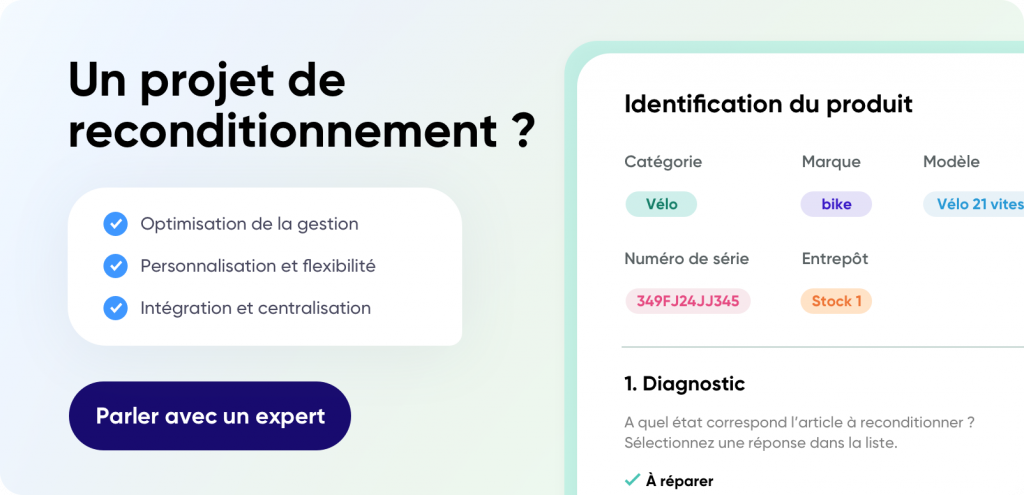

Refurbishment software is a technological solution designed to manage and optimize the product refurbishment process.

At its core, it automates repetitive tasks, tracks inventory, manages spare parts, and ensures quality control.

These tools are essential for businesses seeking to improve their operational efficiency and ensure every refurbished product meets high quality standards.

Comparison between Refit and manual solutions like Excel or paper

Refit clearly stands out from manual solutions like Excel or paper.

| Criteria | Paper | Excel | Refit |

|---|---|---|---|

| Traceability | ❌ Very limited | ⚠️ Manual | ✅ Automatic and complete |

| Update time | ❌ Very long | ⚠️ Human intervention required | ✅ Real-time |

| Error risk | ❌ Very high | ⚠️ High | ✅ Minimized |

| Data security | ❌ None | ⚠️ Limited | ✅ Secured |

| Team collaboration | ❌ Impossible | ⚠️ Difficult | ✅ Optimized |

| Automatic reports | ❌ Non-existent | ⚠️ Manual | ✅ Automatic |

Risks of manual methods

With Excel, every update requires human intervention, which is not only time-consuming but also error-prone. Paper-based management is even more archaic and offers little traceability or data security.

In contrast, Refit centralizes all relevant information in an intuitive interface.

It enables real-time tracking, detailed reports, and simplified inventory and spare parts management.

This automation reduces errors, improves data accuracy, and frees up time for employees, who can focus on higher-value tasks.

The advantages of refurbishment software for your business

Optimized refurbishment scenarios

One of the main advantages of refurbishment software like Refit is the optimization of refurbishment scenarios.

Through advanced automation and integrated intelligence, Refit allows you to create efficient workflows that reduce product processing time and minimize errors.

Customization by product type

Imagine being able to configure specific scenarios for different product types. For example, smartphones and laptops require different refurbishment processes.

With Refit, you can customize refurbishment steps for each product category, ensuring each step is executed optimally.

Furthermore, Refit continuously analyzes performance data to identify bottlenecks and suggest improvements.

This means your refurbishment process becomes increasingly efficient over time, allowing you to save resources and improve customer satisfaction.

Cost and team management

Cost management is crucial for any business, and refurbishment software like Refit can make a significant difference.

By automating many manual tasks, Refit reduces the need for labor, resulting in significant savings.

Additionally, the software enables precise tracking of costs associated with each step of the refurbishment process.

Team management benefits

- Task assignment: Automatic assignment based on skills

- Real-time tracking: Progress visible instantly

- Needs identification: Automatic detection of areas requiring training

- Harmonious environment: Reduced stress through organization

Refit also offers powerful tools for team management.

You can assign specific tasks to each team member, track their progress in real-time, and identify areas where additional training might be needed.

This proactive human resource management not only improves efficiency but also creates a more harmonious and productive work environment.

By integrating dashboards and detailed reports, Refit provides an overview of costs and team performance.

This enables managers to make informed decisions to optimize operations and maximize return on investment.

Spare parts management

Spare parts management is often a major challenge in product refurbishment.

Refurbishment software like Refit greatly simplifies this task by centralizing all information related to spare parts.

Key features for spare parts:

- Real-time tracking: Stock levels, inputs and outputs visible instantly

- Automatic alerts: Notifications when levels are low

- Automated ordering: Scheduled replenishment according to defined thresholds

- Complete traceability: History of every movement recorded

With Refit, you can track spare parts inventory in real-time, receive alerts when levels are low, and even automate replenishment orders.

This ensures you always have the necessary parts at hand, avoiding delays in the refurbishment process.

Traceability and warranties

Refit enables tracking of each spare part usage, ensuring complete transparency and full traceability. You can easily identify which parts were used in which product, which is essential for warranty and return management.

In summary, spare parts management with Refit becomes more efficient, accurate, and less stressful, allowing your business to focus on continuously improving its refurbishment processes.

By adopting refurbishment software like Refit, you can transform how your business manages refurbishment, optimizing refurbishment scenarios, controlling costs, and improving team and spare parts management.

These combined benefits can lead to increased efficiency, reduced costs, and improved customer satisfaction.

How does refurbishment software work?

Main features of Refit

Refit is designed to offer a comprehensive range of features that make refurbishment more efficient and manageable.

Among its main features are:

🔄 Task automation: Refit automates repetitive tasks, reducing human errors and increasing processing speed.

📦 Inventory management: The software enables real-time inventory tracking, facilitating spare parts needs planning.

📊 Data analysis: Through integrated analysis tools, Refit provides detailed performance reports, helping managers make informed decisions.

🖥️ Intuitive user interface: Refit is designed to be easy to use, with a clear and intuitive interface requiring minimal training.

These features enable Refit to stand out as a powerful and comprehensive refurbishment solution.

Automated refurbishment process with Refit

Automation is at the heart of what makes Refit so effective.

The automated refurbishment process begins as soon as a product is received.

Automated process steps

- Reception and sorting: Automatic scanning and registration

- Inspection and diagnosis: Step-by-step technician guidance

- Repair: Automatic identification of necessary parts

- Quality control: Verification according to predefined standards

📥 Reception and sorting: Products are scanned and registered in the system, where Refit automatically classifies them according to predefined criteria.

🔍 Inspection and diagnosis: Refit guides technicians through a series of steps to inspect and diagnose product issues, ensuring nothing is overlooked.

🔧 Repair and parts replacement: The software identifies necessary parts and checks stock availability. Technicians are then guided to perform repairs in a standardized and efficient manner.

✅ Quality control: Once repairs are completed, Refit manages rigorous quality control to ensure each product meets the company's high standards.

This process automation reduces processing times and increases accuracy, resulting in better quality refurbished products.

Tracking and management of refurbished inventory with Refit

Inventory management is another key feature of Refit.

Through advanced tracking tools, the software ensures efficient management of refurbished inventory.

📈 Real-time tracking: Refit enables real-time tracking of inventory levels, parts inputs and outputs, and finished products.

This helps avoid stockouts and excess inventory.

📋 History and traceability: Every inventory movement is recorded, providing complete traceability of parts and products.

This is crucial for warranty management and after-sales service.

⚡ Inventory optimization: Refit analyzes inventory data to identify trends and optimize replenishment levels, reducing storage costs and production delays.

Benefits of automated inventory management

- Reduction in storage costs by 15 to 25%

- Decrease in stockouts by 80%

- Improvement in inventory turnover by 30%

In summary, Refit transforms inventory management into a smooth and well-organized process, maximizing efficiency and minimizing interruptions in the refurbishment flow.

By adopting Refit, your business benefits from a fully integrated refurbishment system that automates key processes, improves inventory management, and ensures complete traceability, guaranteeing optimal operational efficiency and superior quality of refurbished products.

Criteria for choosing the right refurbishment software

Ease of use and technical support

When choosing refurbishment software, ease of use is an essential criterion.

Intuitive and easy-to-learn software allows your teams to focus on their main tasks without wasting time on training.

Refit stands out with its clear and user-friendly interface, designed to minimize learning time and maximize productivity.

The importance of technical support

Good software must be backed by a responsive and competent support team, ready to solve problems quickly. Without adequate support, even the best software can become a hindrance to your business.

Technical support is also crucial.

Refit offers quality technical support, with experts available to assist you when needed, ensuring your refurbishment operations run smoothly.

Industry-specific features

Each industry has its own needs and requirements.

It's therefore important to choose refurbishment software that offers features tailored to your industry.

Refit is designed to be flexible and customizable, allowing businesses to configure the software according to their specific needs.

Examples of customization by industry:

- Electronics: Component management, performance testing, warranty management

- Furniture: Material management, finishes, restoration processes

- Automotive: Parts traceability, safety standards, maintenance cycles

- Medical: Regulatory compliance, sterilization, certifications

For example, electronics refurbishment companies can benefit from specific features such as electronic component management, performance testing, and warranty management.

Conversely, a furniture refurbishment company might need features for material and finish management.

Refit offers an extensive range of customizable features, making the software adaptable to various refurbishment sectors, allowing each business to get the most out of its processes.

Essential selection criteria

- ✅ Ease of use and intuitive interface

- ✅ Responsive and competent technical support

- ✅ Features adapted to your industry

- ✅ Flexibility and customization

- ✅ Measurable return on investment

Choosing the right software involves considering ease of use, technical support, industry-specific features, as well as cost and return on investment.

With Refit, you benefit from a complete and proven solution, ready to meet all your refurbishment needs.

Bonus: Industries for which Refit is most suitable

Refit is a versatile and robust solution, designed to adapt to a variety of industries.

Thanks to its flexibility and advanced features, Refit can transform refurbishment operations across multiple sectors.

Here are some industries where Refit can really make a difference:

Home appliances

The home appliance sector greatly benefits from Refit thanks to its component management capabilities and spare parts tracking.

Whether it's refrigerators, washing machines, or ovens, Refit helps manage repair and refurbishment processes, ensuring each appliance is inspected and restored to the highest standards.

IT equipment

For IT equipment refurbishment companies, Refit offers specific features like electronic component management, performance testing, and software management.

Whether for computers, servers, or peripherals, Refit optimizes every step of the refurbishment process, from initial inspection to final delivery.

Industrial machinery

Refurbishing industrial machinery requires particular attention and rigorous management of parts and processes.

Refit enables tracking of every spare part, planning repairs, and managing preventive maintenance cycles, ensuring refurbished machines operate optimally and durably.

Furniture

In the furniture sector, Refit helps manage materials, finishes, and restoration processes.

Whether it's wooden, metal, or upholstered furniture, Refit ensures each piece is carefully restored and ready for reuse.

Material inventory management and process traceability are major assets for companies in this sector.

Consumer electronics

Refit is particularly effective for refurbishing consumer electronics such as smartphones, tablets, and televisions.

Thanks to its advanced diagnostic features and parts management, Refit ensures each device is accurately restored, reducing return rates and increasing customer satisfaction.

Vehicles and automotive parts

Refurbishing vehicles and automotive parts is an area where Refit excels.

The software enables managing spare parts inventories, planning repairs, and ensuring traceability of used parts.

This guarantees that every refurbished vehicle or part meets safety and performance standards.

Medical equipment

The medical equipment sector requires extreme rigor and precision.

Refit offers tracking and parts management features that are crucial for medical equipment refurbishment.

Additionally, the software helps maintain high quality standards, ensuring every refurbished equipment is safe and effective.

Sports equipment

For sports equipment, whether bicycles, fitness equipment, or sports gear in general, Refit ensures efficient management of parts and repair processes.

This allows businesses to reliably refurbish equipment and maintain high performance standards.

Excellence sectors for Refit

| Sector | Key advantages | Average ROI |

|---|---|---|

| Home appliances | Component management + traceability | +35% |

| IT equipment | Automated testing + software management | +40% |

| Industrial machinery | Preventive maintenance + scheduling | +45% |

| Automotive | Safety standards + parts traceability | +30% |

| Medical | Regulatory compliance + quality | +50% |